Hidden Rust Zones on Beetles, Buses, and Ghias: Where a Classic VW PPI Saves You Thousands

📌 Key Takeaways

Request specific underside photos before viewing any classic VW to avoid wasting time on rust-compromised vehicles.

- Photos Reveal Hidden Problems: Requesting underside shots, door sill close-ups, and seam photos exposes structural rust before you drive hours to view a car.

- The 1-3 Scale Guides Decisions: Surface rust (Level 1) is manageable, localized perforation (Level 2) requires negotiation, and structural compromise (Level 3) demands walking away or major price adjustments.

- Heater Channels Hide Expensive Damage: Beetle heater channels and Bus outriggers rust from inside first, compromising safety and door alignment before visible perforation appears.

- Professional Inspections Provide Leverage: On-lift access and documented severity assessments transform vague concerns into specific negotiating points with clear repair priorities and realistic cost projections.

Smart photo requests filter out problem cars before emotional attachment begins.

Classic VW buyers around Orange County will gain practical rust-spotting skills here, preparing them for the detailed inspection process that follows.

Pretty paint can hide budget-changing structural problems. A classic VW listed as "clean" might photograph beautifully in seller photos, but structural rust often lives where cameras don't reach—underneath panels, inside seams, and along load-bearing channels. For buyers around Orange County considering a Beetle, Bus, or Karmann Ghia, understanding these hidden zones transforms uncertainty into a clear decision: buy, walk, or renegotiate with confidence.

The Fast Way to Avoid a Rust Money Pit (Before You Fall in Love)

Before you drive two hours to view a car, request specific photos from the seller. Ask for clear shots of the underside, close-ups of door sills from straight-on and angled views, pictures of seam areas where panels meet, and images of known water-trap zones. These aren't accusatory questions—they're standard practice for anyone serious about a classic VW purchase.

Photos to request (buyer-safe, no tools required):

- Underside wide shots: front-to-back, both sides (not just one "best angle")

- Close-ups of seams and edges: where panels overlap and trap moisture

- Door sills/rocker area: both sides, straight-on and angled

- Floor areas: front footwells, rear footwells, and around any mats

- Battery area (Beetle in particular): the area where battery acid spills and road spray accelerate corrosion from the bottom up.

- Windshield corners and rain gutters (Bus especially): leak paths become rust paths

- Any bubbling paint: close-ups plus a step-back photo for context

- Front beam/axle mounting points (Bus/Beetle): Look for 'oil-canning' or stress cracks in the frame head.

If a seller hesitates or avoids these requests, that's a signal, not a verdict. Some owners simply haven't looked closely at these areas themselves. Others may know what's there and prefer you discover it in person. Either way, the response tells you something useful before you invest time and emotion.

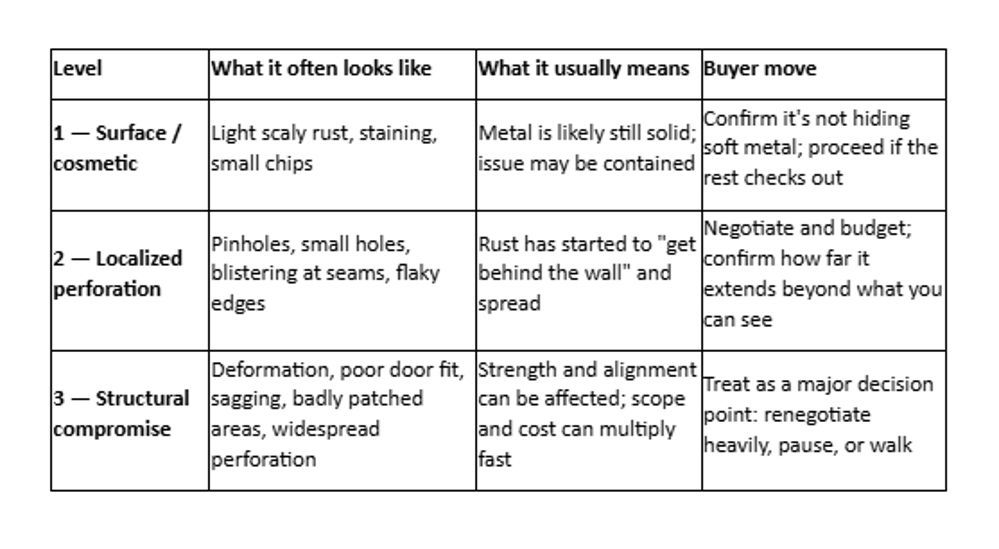

Rust Severity in Plain English: The 1-3 Scale

Not all rust carries the same weight in a buying decision. Understanding severity helps you separate manageable projects from budget-busting rebuilds.

The key question at Scale 1: is it truly surface-level, or is it hiding soft metal underneath? A magnet test can reveal body filler, and a careful inspection confirms whether the rust is contained or spreading.

At Scale 2, rust has eaten through the metal in specific spots—often at seam edges, drain holes, or lower body sections. This level changes the negotiation because repair costs become real and measurable. Document the boundaries carefully. If perforation is limited to a replaceable panel and hasn't spread to adjacent structure, it may still be worth proceeding with adjusted expectations and budget.

Scale 3 is the category that fundamentally alters a purchase decision. Rust has compromised load-bearing channels, floor pan supports, or frame sections that affect safety and require extensive metalwork. Repairs often cascade—fixing one compromised area reveals adjacent damage. At this severity, you're not buying a car to drive; you're buying a restoration project. That's fine if the price reflects reality and you're prepared for the scope, but it's a different commitment entirely from what most buyers expect when they see attractive photos online.

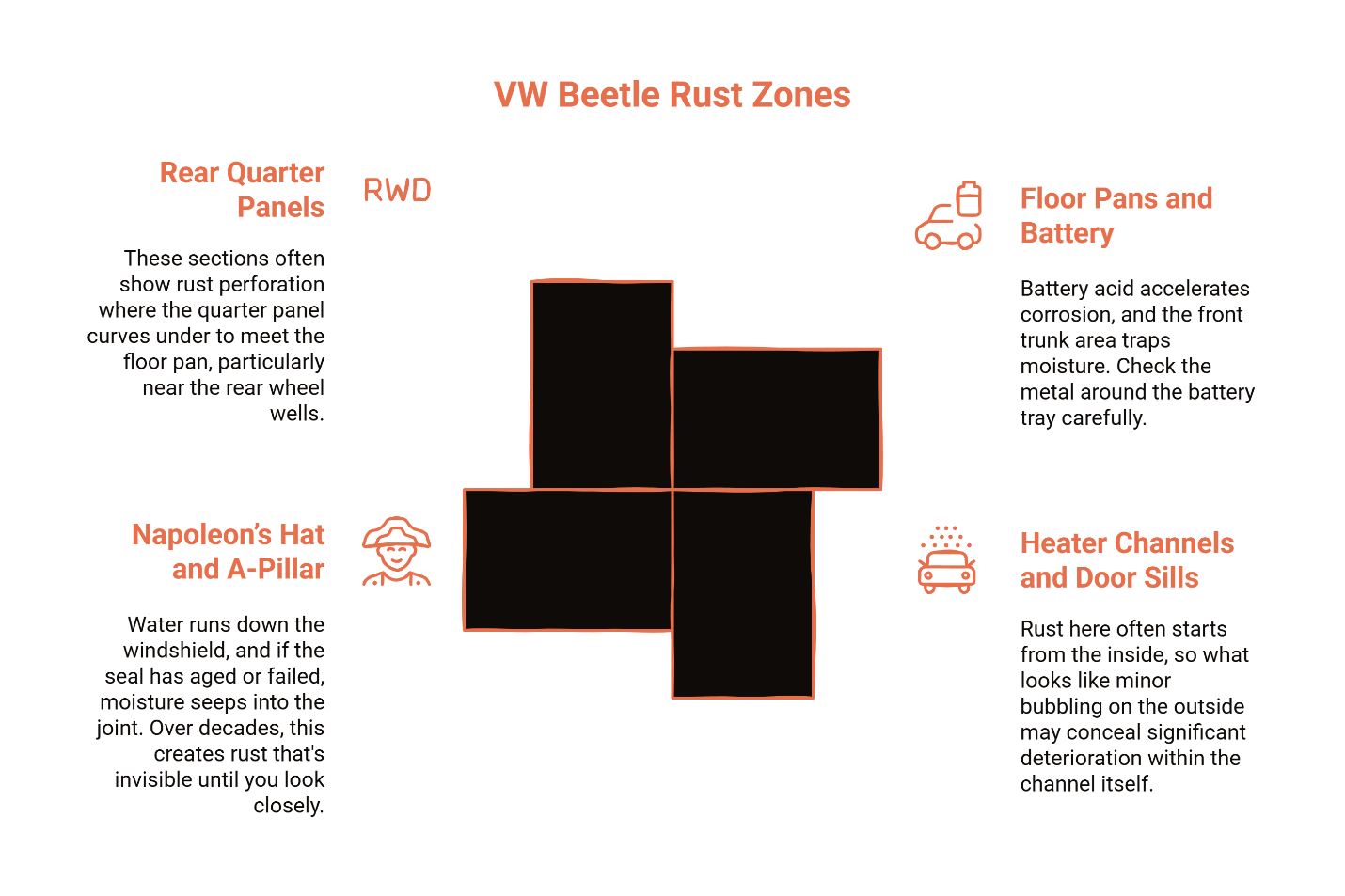

Hidden Rust Zones on VW Beetles (Type 1)

Beetles hide their worst rust in predictable places, usually where water collects and sits unnoticed for years.

The floor pans and battery area are notorious. Battery acid accelerates corrosion, and the front trunk area where the spare tire sits often traps moisture from leaks around the hood seal. Check the metal around the battery tray carefully, and look for rust perforation where the floor pan meets the body at the front.

Heater channels and door sills run along the lower body sides serve as the primary longitudinal structural members of the chassis. When these rust through, doors don't close properly, jacking becomes unsafe, and the body loses rigidity. Rust here often starts from the inside, so what looks like minor bubbling on the outside may conceal significant deterioration within the channel itself.

The 'Napoleon’s Hat' (the chassis bulkhead) and the A-pillar/heater channel junction constitute the most critical structural intersection and heater channel front-sections are another vulnerable point. Water runs down the windshield, and if the seal has aged or failed, moisture seeps into the joint. Over decades, this creates rust that's invisible until you look closely at the base of the windshield pillar from underneath.

Rear quarter panels at the lower edges and the running board areas collect road spray and hold moisture against metal. These sections often show rust perforation where the quarter panel curves under to meet the floor pan, particularly near the rear wheel wells.

Hidden Rust Zones on VW Buses (Type 2)

Bus rust tends to be more expensive to address than Beetle rust because of the vehicle's size, structural complexity, and the difficulty of panel replacement. This is where water damage behind paint becomes a scope-multiplier—one leak path can create multiple rust zones that connect and spread.

Rockers, outriggers, and jack points are critical structural areas on a Bus. The outriggers—metal supports that extend from the frame to create jacking points—these hollow box sections often trap condensation and road salt, rotting from the inside out. Structural integrity is often compromised before visual perforation occurs; a 'hammer tap' test or bore-scope inspection is required to verify the inner box-section wall thickness. This is a safety issue. If these areas have failed, the vehicle can't be safely lifted for service, and the structural integrity of the entire body is compromised.

The front floor and lower nose area take direct road spray and often show rust where the front body panel meets the floor. Check the seams carefully and look for previous repairs that might indicate recurring issues.

Cargo floor edges and seams are where water from wet cargo or cleaning has historically pooled. Buses used for camping or work often have floor rust because moisture had nowhere to escape. Look at the edges where the floor meets the side panels and check around any drain holes to see if they're clear or if rust has sealed them shut.

Rain gutters and the windshield area channel water away from the vehicle, but when these gutters rust or when windshield seals fail, water runs down into the body cavity and causes hidden corrosion. The lower corners of the windshield frame and the body cavity behind the dash are common failure points.

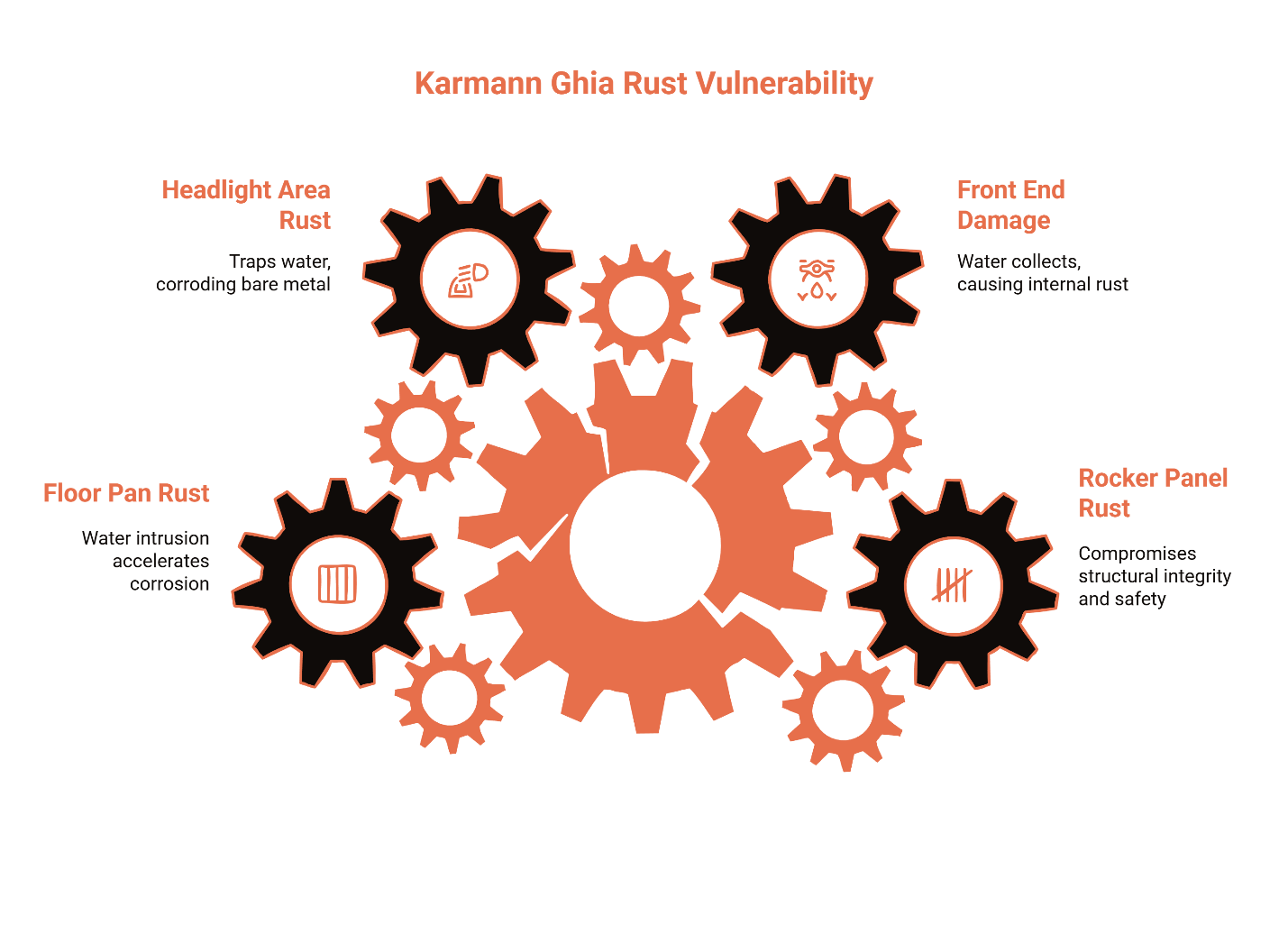

Hidden Rust Zones on Karmann Ghias (Type 14)

Karmann Ghias share the Beetle's platform but add Italian coachwork with unique rust vulnerabilities.

Rockers and lower body structure serve the same load-bearing function as Beetle heater channels. Rust here affects door fit, structural integrity, and jacking safety. Because Ghia body panels are more complex and harder to source than Beetle parts, repairs are often more expensive.

The nose and lower front sections sit low and take road damage. Water collects in the front cavity, and rust often starts from the inside. Check the seam where the nose panel meets the floor pan and inspect the lower curves of the front fenders.

Headlight bucket areas and lower fenders trap water and debris. Water enters through deteriorated seals or stone chips and sits against bare metal. Rust in the lower fenders often spreads upward, and because Ghia fenders have compound curves, repairs require skilled metalwork or expensive replacement panels.

Floor pan edges and rear lower body areas follow the same pattern as Beetles—water intrusion combined with age equals rust. The rear quarters where the body curves under toward the floor pan are particularly vulnerable.

What a Classic VW Pre-Purchase Inspection Does Differently for Rust

A proper classic car maintenance and pre-purchase inspection changes the equation because it provides visibility, documentation, and a severity assessment that photos from a seller can't match.

On-lift access reveals what's hidden. A technician can see the underside structure, check seam integrity, and assess rust from angles impossible to capture in driveway photos. Areas that look acceptable from above often tell a different story from below.

Detailed documentation creates a clear record of findings tied to specific locations. Instead of vague descriptions, you receive thorough notes showing exactly where rust exists, how extensive it is, and what surrounding areas look like. These findings become reference points for negotiation, repair planning, or the decision to walk away.

Severity classification translates observations into actionable information. Rather than simply noting "rust present," a thorough inspection categorizes findings using a framework similar to the 1-3 scale described earlier. This helps buyers understand whether they're looking at a weekend project, a significant repair commitment, or a full restoration.

The inspection findings roll into a prioritized plan if you proceed with the purchase. Must-do items that affect safety or prevent further damage, soon items that should be addressed within the first year, and monitor items that need attention eventually but aren't urgent. This structure helps buyers budget realistically and understand what they're taking on.

What You Should Expect to Receive After the Inspection

A well-executed vehicle inspection delivers clarity in three key areas.

Clear documentation of rust areas, structural concerns, and areas of particular vulnerability. The inspection record should be detailed enough that you can reference it when discussing the vehicle with other mechanics, body shops, or when making repair decisions later.

Thorough notes using buyer-friendly language—not technical jargon that requires translation. Findings should explain what the rust is, why it matters to the vehicle's function and value, and what changes it makes to the purchase decision. Phrases like "must address immediately," "plan for within six months," or "monitor during regular maintenance" help you prioritize and budget.

A realistic assessment of how findings affect your decision. Not every classic VW needs to be perfect. The right car with documented issues and an adjusted price can be a better buy than an unknown car at full market value. What matters is that you understand the condition, the costs, and the commitment before making an offer.

Frequently Asked Questions

Where do VW Beetles rust the most?

Beetles rust most commonly in floor pans (especially near the battery), heater channels, lower door sills, the base of the A-pillars near the windshield, and lower rear quarter panels. These areas trap moisture and are often hidden from casual inspection.

Where do VW Buses hide structural rust?

Buses develop serious rust in rockers, outriggers that serve as jack points, front floor sections, cargo floor edges, and around the windshield frame. Because Bus repairs involve more complex panel work, structural rust often costs more to address than similar issues on Beetles.

Do Karmann Ghias rust in different places?

Ghias share many rust zones with Beetles due to the shared platform—rockers, floor pans, and lower body areas. However, Ghia-specific concerns include the lower nose section, headlight buckets, and complex fender curves that make repairs more difficult and expensive.

Is surface rust a deal-breaker on a classic VW?

Surface rust by itself isn't typically a deal-breaker if it's truly superficial and hasn't spread. The critical question is whether it's hiding deeper problems. Confirm that the metal underneath remains solid, check adjacent areas for spreading corrosion, and ensure the rust hasn't compromised structural components.

What should a classic VW pre-purchase inspection include?

A thorough inspection should include on-lift examination of the underside, detailed documentation of all rust areas, checking structural load-bearing sections like heater channels or outriggers, testing floor pan integrity, and assessing seam condition where panels join. The inspection should conclude with a clear severity assessment and prioritized findings that help guide your purchase decision. Our family-owned shop since 1971 has extensive experience with classic VWs and provides comprehensive inspections that give buyers the information they need.

When to Call (and What to Send Us)

If you're considering a classic VW purchase around Orange, Anaheim, Villa Park, Tustin, or Yorba Linda, we can help you understand what you're looking at before you commit. Text us photos from the listing or from your initial viewing—rust bubbles, seam areas, or underside shots. Even a few clear images can start a useful conversation about what questions to ask the seller and whether a full inspection makes sense.

Don't hesitate to reach out with questions. We'd rather help you avoid a problem car than profit from an inspection that confirms what you already suspected.

Orange Independent Auto Repair

(714) 633-7161

187 S Main St, Orange, CA 92868

Monday–Friday: 7:00 AM – 6:00 PM

Saturday: By appointment only

Schedule a pre-purchase inspection or call to discuss what you're seeing in seller photos. We're here to help classic VW buyers make informed decisions with confidence.

Disclaimer: This article provides general educational information about common rust areas in classic Volkswagens and the purpose of pre-purchase inspections. Vehicle conditions vary significantly, and rust severity can only be properly assessed through in-person inspection by qualified technicians. Always consult with a professional mechanic before making purchase decisions on classic vehicles.