Engine Health on a Vintage VW: What Compression and Leakdown Numbers Mean for Buyers

📌 Key Takeaways

Compression and leakdown tests reveal a vintage VW engine's true condition before you buy, turning vague seller claims into negotiable facts.

- Consistency Trumps Numbers: All four cylinders within ±10% of each other matters more than hitting a specific PSI target.

- Calculate the Spread: Divide the cylinder difference by the highest reading to quantify imbalance and identify problem holes.

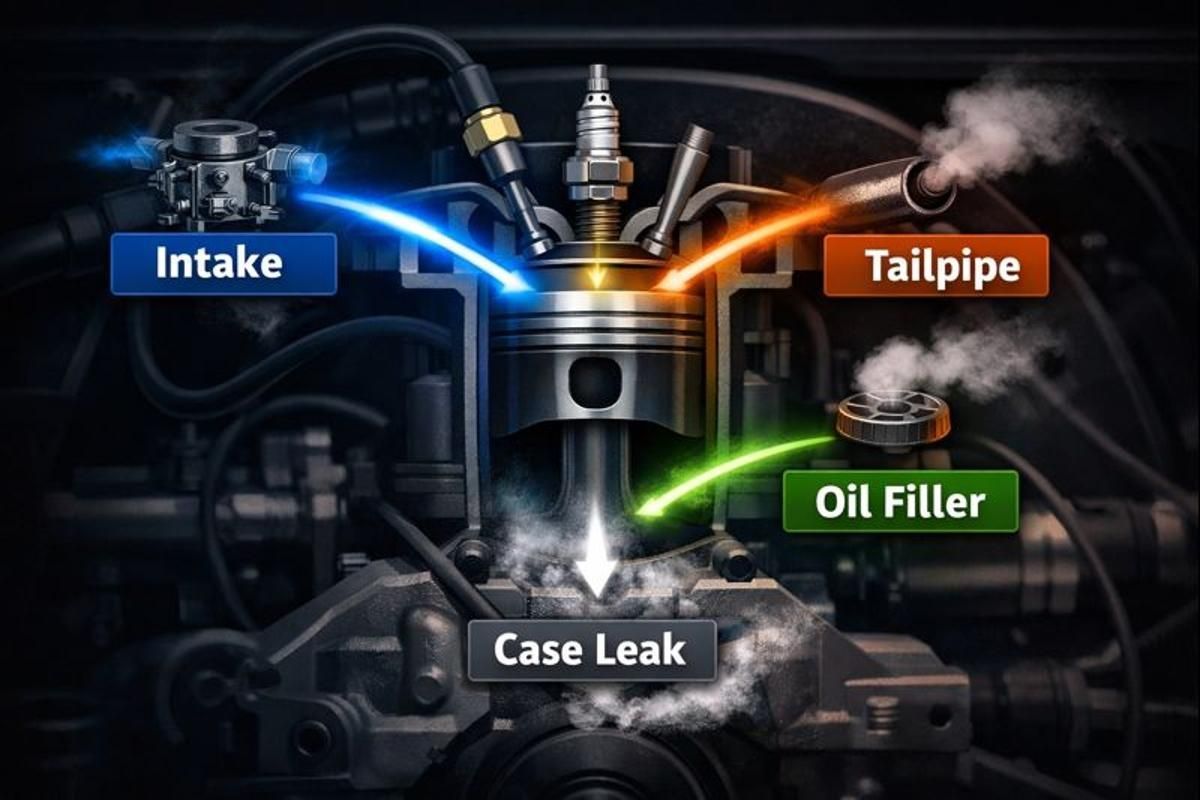

- Listen to Locate Leaks: Where air hisses during leakdown—intake, tailpipe, or breather—pinpoints whether valves or rings need work.

- Document Creates Leverage: Detailed written reports with specific readings per cylinder give you negotiating power and future maintenance baselines.

- Interpret Through Action Buckets: Sort results into "must-fix now," "plan soon," or "monitor" categories to structure offers and ownership budgets.

Measured data beats seller stories every time.

Classic VW buyers in Orange County evaluating Beetles, Buses, and Ghias will gain pre-purchase confidence here, preparing them for the diagnostic details that follow.

Numbers beat guesswork. Here is how compression and leakdown tell the true story of a classic VW engine—without spinning wrenches.

You're standing in a driveway in Orange, looking at a '67 Beetle that could be perfect. The paint looks right. The interior's clean. The seller says it runs great. But what's actually happening inside those cylinders? Before you hand over cash or sign paperwork, two simple tests—compression and leakdown—give you the objective health report you need to buy confidently, negotiate fairly, or walk away.

The Two Tests That Anchor an Air-Cooled VW PPI

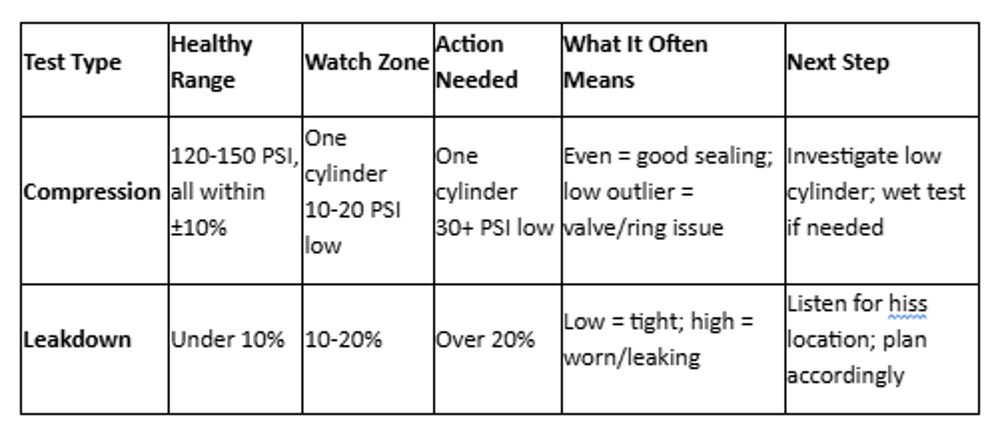

A compression test measures cranking pressure. The engine turns over, and a gauge captures the peak PSI each cylinder produces during the compression stroke. It's a snapshot taken while the engine spins.

A leakdown test measures percentage of leakage when the cylinder sits at top dead center. Regulated air goes in; the gauge shows how much escapes. This differential-pressure approach reveals not just how much air leaks, but where it's going—giving you diagnostic clues about the specific component that's failing. Where you hear the hiss—intake manifold, tailpipe, oil filler, or crankcase—tells you what's leaking.

Why do both? Because they reveal different things. Compression shows whether cylinders build pressure. Leakdown shows where that pressure goes. An engine can post decent compression numbers but still leak heavily through worn rings or valve seats. Conversely, older air-cooled engines often run lower absolute PSI than modern water-cooled mills, yet perform beautifully when all four cylinders are consistent.

Here's the truth: uniformity across cylinders often matters more than hitting a specific PSI target. Think of it like a home inspection before you sign—you're looking for red flags and imbalances that signal trouble ahead, not chasing perfection on a vintage platform where "perfect" varies by build, altitude, and the gauge itself.

Ranges, not promises. Engines vary by displacement, compression ratio, carburetor setup, elevation, and even how the test was performed. What follows are practical bands that help you make decisions, not factory specifications carved in stone.

Interpreting Compression: Absolute vs. Relative "Good"

A healthy Type 1 VW engine typically shows 120–150 PSI per cylinder, though some built-up motors run higher and some stock 1600s at altitude run lower. The critical measure: all four holes should fall within about ±10% of each other—a guideline documented in professional compression testing equipment standards. If cylinder 1 reads 140 PSI and the other three cluster around 135–145, that's balanced. If cylinder 3 drops to 110 while the others stay near 140, you've found a problem.

Calculating the spread: Take the highest cylinder reading minus the lowest, then divide by the highest. If your highest reads 130 and your lowest reads 118, the math is simple: (130 - 118) ÷ 130 = 9.2%. That falls within the acceptable range. But if three cylinders read 130 and one reads 95, you're looking at (130 - 95) ÷ 130 = 27%—well beyond the threshold and a clear signal that something's wrong with that cylinder.

Red Flags in Compression Results

One low cylinder often points to a worn valve, broken ring, or head gasket issue on that specific jug. Adjacent cylinders both reading low can suggest a head gasket leak between them or a shared valve-sealing problem on that head. When a cylinder improves significantly with a "wet test"—adding a squirt of oil before re-testing—it points to worn rings, because the oil temporarily seals the ring-to-wall gap and boosts pressure.

Context Matters for Repeatability

Throttle position, engine temperature, starter speed, and gauge calibration all affect readings. The engine should be warm, the throttle plate wide open, and the test conducted with a known-good gauge. A weak battery that cranks slowly will produce lower numbers than a fresh battery spinning the engine at normal speed. This doesn't mean the engine is bad; it means the test setup introduced a variable.

Understanding these factors helps you evaluate whether a set of numbers reflects true engine condition or just measurement variance. Measurement science teaches us that all mechanical tests carry inherent uncertainty—which is exactly why standardized procedures and thorough documentation matter so much. At Orange Independent Auto Repair, we've been testing classic VWs for over 50 years, and we've seen how small differences in procedure can shift results by 10–15 PSI—which is why we standardize our process and document everything with detailed written reports.

Interpreting Leakdown: What the Air Is Telling You

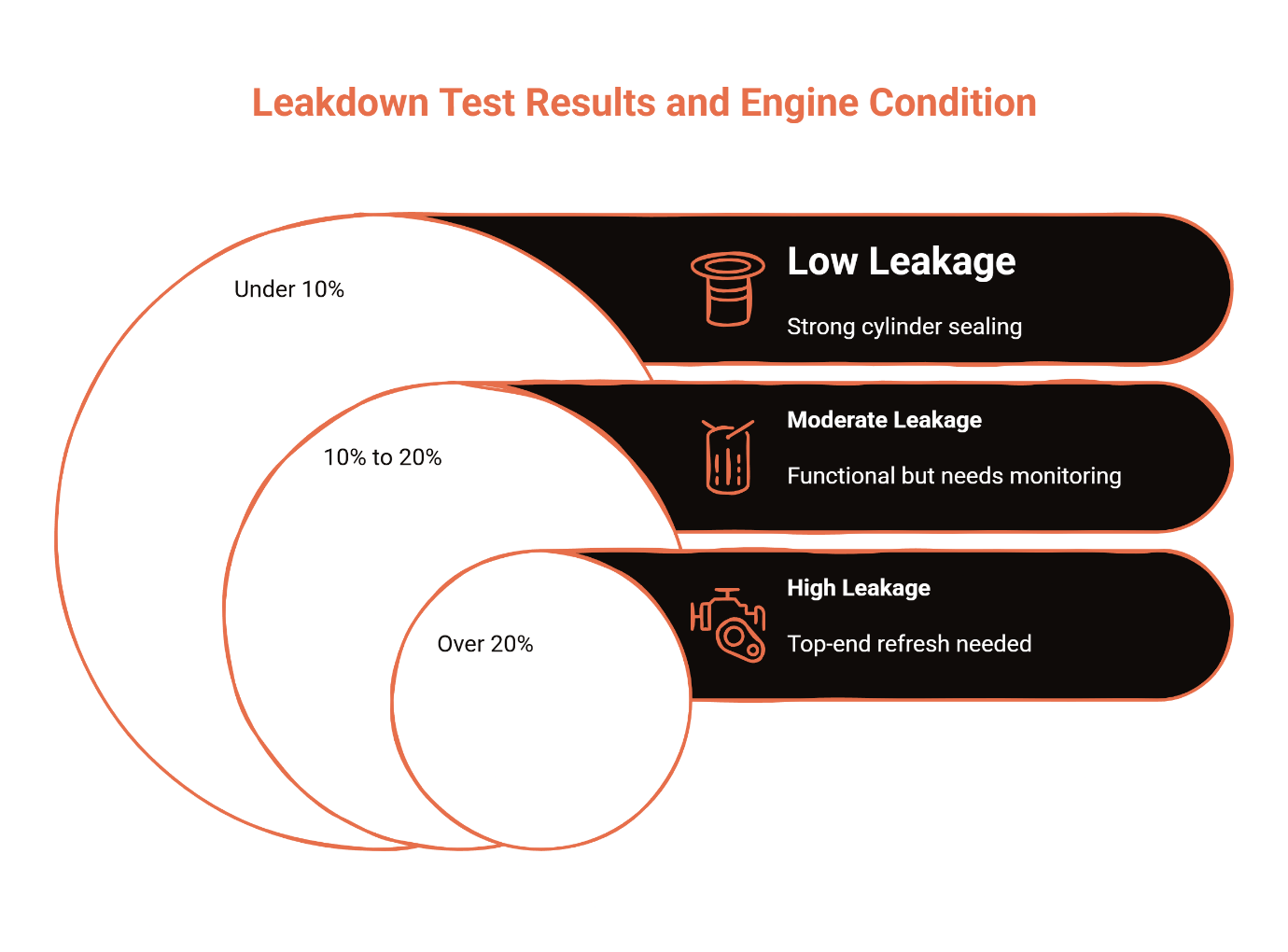

Leakdown results come as percentages. Low leakage—under 10%—indicates strong cylinder sealing and typically falls into the "good" category in automotive training materials. Moderate leakage—10% to 20%—means the engine is still functional but worth watching and planning for eventual work, often considered "acceptable" for serviceable engines. High leakage—over 20%—often signals that a top-end refresh or overhaul is in your near-term budget, and commonly triggers the "unacceptable/investigate" flag in professional diagnostics.

But the percentage alone doesn't tell the full story. Where you hear the air escaping reveals the likely source.

Where You Hear It Equals the Likely Source

Listen at the intake manifold. A hiss there suggests an intake valve isn't sealing properly against its seat. Listen at the tailpipe. Air rushing out points to an exhaust valve issue. Listen at the oil filler cap or breather. A strong whoosh indicates the air is bypassing the rings and pressurizing the crankcase—classic ring wear. Occasionally, you'll hear air escaping from the case itself, which can indicate a crack or other structural issue.

These listening points act like a diagnostic map, and they're taught consistently across professional automotive training programs. One cylinder showing 15% leakage with air hissing loudly from the tailpipe tells you that exhaust valve likely needs attention. Another cylinder at 15% leakage with air roaring from the breather suggests worn rings or cylinder wall glazing.

Trend Beats One-Off Data

A single leakdown test establishes a baseline. The real value comes from trending over time. If you buy the car and test it again in six months, you can see whether leakage is stable, improving after a valve adjustment, or getting worse. That trend informs your maintenance and rebuild planning far better than a single snapshot ever could.

"Eddie has been working on VW Beetles for 50+ years. He's the only person that will ever touch my car. I have received nothing but exceptional service from Orange Independent." —Ty M., Long Beach (Yelp)

Putting Numbers to Work: Offer and Ownership Planning

Raw data becomes actionable when you convert it into a decision framework. Here's how to translate test results into next steps.

Must-Do Now. Extreme leakdown on one cylinder—say, 30% or higher with air screaming from the tailpipe—means that valve or seat needs immediate attention to avoid further damage. If compression on that same cylinder is 40 PSI below the others, you're looking at urgent work. Factor this into your offer or walk if the seller won't adjust the price to cover a top-end job.

Soon. Moderate leakdown across all cylinders—12% to 18%—with even compression suggests the engine is running on borrowed time but not in crisis. Plan and budget for a refresh in the next 6–12 months. Use this information to negotiate a modest price reduction or simply accept that you'll be investing in the engine after purchase.

Monitor. Low, balanced leakdown under 10% and compression within ±10% across all four cylinders means the engine is in good shape. Stick to regular classic VW maintenance and tuning, check valve adjustment periodically, and enjoy the drive. Retest annually to catch any developing trends early.

This framework aligns perfectly with the "research online, buy offline" approach that works best for classic car purchases. You gather the diagnostic facts, interpret them using clear guidelines, and then book an appointment to finalize your plan with a trusted shop that understands air-cooled engines.

Documentation Builds Trust

Words are easy. Numbers on paper can be questioned. Detailed written reports with specific gauge readings—one per cylinder, clearly labeled—provide the hard evidence you need. When you arrange a pre-purchase and vehicle inspection, ask for a comprehensive written summary that includes each compression reading and each leakdown percentage. Request notes on where the air was heard escaping during the leakdown test.

A thorough written report beats twenty adjectives. It shows you exactly what the technician observed, and it gives you documentation to reference later when planning repairs or negotiating with the seller. This documentation-first approach is how we've built trust locally since 1971—by providing detailed, verifiable reports rather than vague assurances.

Here's what differentiates this method from the typical "fast and cheap" pitch you'll find elsewhere: measured diagnostics and transparent documentation create a baseline you can trust. You're not relying on someone's opinion that the engine "seems strong." You're looking at quantified data that reveals the actual condition, backed by written documentation of every measurement.

Buyer's Quick-Reference Card: VW Engine Numbers at a Glance

Listen-Here Guide:

- Intake hiss → Intake valve sealing

- Tailpipe hiss → Exhaust valve sealing

- Oil filler rush → Rings/cylinders

- Case leak → Structural issue

Rule of Thumb: Consistency across cylinders matters more than absolute numbers.

Next Steps in Orange, CA

Bring the car to Orange Independent Auto Repair at 187 S Main St, Orange, CA 92868 for a comprehensive pre-purchase inspection that includes compression testing, leakdown testing, and a detailed written summary. Our team has specialized in classic VW diagnostics for decades, working on everything from early split-window Buses to late-model Super Beetles.

We serve buyers and owners throughout Orange County, including Anaheim, Villa Park, Tustin, and Yorba Linda. Whether you're evaluating a Beetle on a Saturday morning or need a second opinion on a Karmann Ghia, we provide the same documented, detailed reporting process that's earned us loyal customers for over 50 years in Orange.

Call (714) 633-7161 or visit us Monday through Friday, 7:00 AM to 6:00 PM. Saturday appointments are available by request. Prefer to describe a symptom or discuss gauge readings first? We'll advise on next steps and help you understand what you're looking at before you schedule anything.

California's Bureau of Automotive Repair provides helpful guidance on what proper documentation should include during repair and inspection transactions—useful context when commissioning any pre-purchase inspection.

Disclaimer: Compression and leakdown testing provide valuable diagnostic information, but results can vary based on testing procedures, equipment calibration, engine build specifications, and altitude. The ranges and guidelines presented here are general principles for air-cooled VW engines and should not replace a thorough inspection by a qualified technician. Always consult a professional for specific recommendations based on your vehicle's condition.

Our Editorial Process

At Orange Independent Auto Repair, we combine over five decades of hands-on experience with classic Volkswagens with a commitment to transparent, thoroughly documented diagnostics. This content reflects real-world practices developed through thousands of pre-purchase inspections and engine evaluations since 1971.